Its time for the +3 to get some attention and it appears to have the widest variety of options for trying alternative ways of loading software.

The first method I wanted to try was attaching a 3.5″ Floppy Drive to the machine, to allow loading of games that have been written to disk on a PC. Some methods of utilising a 3.5″ drive involve replacing the internal 3″ drive, but despite my +3 being a little battered and previously unloved, I do feel lucky to have gotten hold of it ,so I do not have a burning desire to start butchering the case. Fitting an internal drive is therefore out of the question.

When I initially researched the problem, I came across this informative forum post on AmiBay, which details adding a 3.5″ external drive using the B: drive port on the back of the Amstrad CPC, which shares some similarities with the Sinclair +3. It also describes making a couple of modifications to the drive itself, but researching further it appears that permanent modifications to the drive are not necessarily required. The HD Floppy sensor could be removed/bypassed, however taping over the hole on a HD disk or using DD floppies would negate the need.

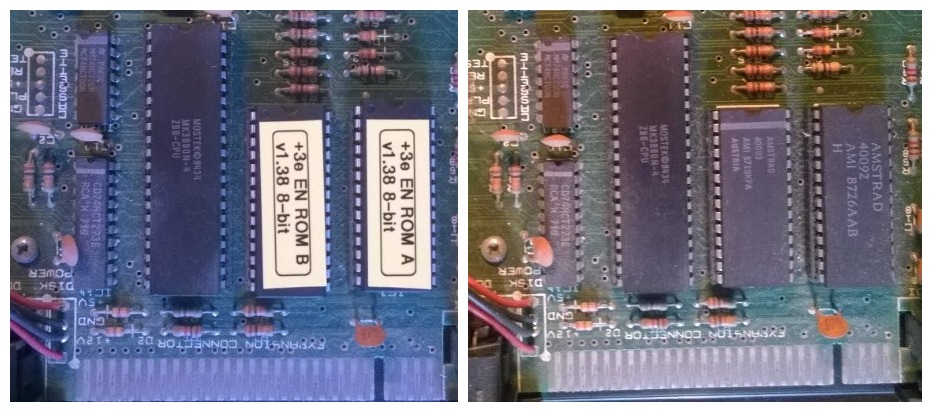

I’ve also read some contradictory information about the requirement for a Ready signal. The Amibay post suggests a solder joint on the drive to force pin 33 low , however part of this WIKI post imply’s that a permanent Ready signal will cause boot problems when a disk is not present. For simplicity and testing, I took a cue from this WIKI ( again a CPC related document ) and decided to make up a small soldered jumper, for fitting between pin 33 and 34, therefore I could add or remove the signal at will.

Putting this all together, I used an old 3.5″ external USB HDD caddy that had the guts removed and a suitable opening on the front cut out to access the floppy drive, once fitted. Using an old PC floppy drive cable, I removed the section of cable after the first 5.25″ drive edge connector, as the Spectrum drive wants a straight through cable and the second half, with a twist, was redundant. I also fitted a small power connector to the case, to accept a +5v ‘wall wart’ PSU, connecting internally to the floppy drive power connector, but using only the +5v pins ( The Amibay post implied that most 3.5″ FDD only require 5v). I also then used my small solder jumper to connect pins 33 and 34 together, by pushing the jumper into the spare 3.5″ drive connector on the cable. Also, after a bit of further reading I realised I might be able to get the external drive to override the internal drive for A: drive for priority, by similarly jumpering pins 11 and 12 ( as per the CPC WIKI article.

A picture is worth a thousand words:

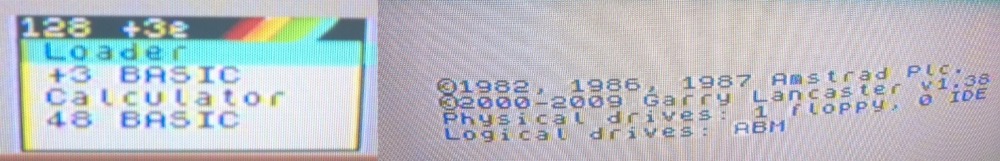

Plugging in didn’t cause my +3 to explode in a shower of sparks, so it passed the first test…

Next I need some disk images. World of Spectrum has some disk images, with an explanation of the Copyright status of the images, from which I downloaded a .dsk file and used Simon Owens SAMDisk utility to write the image to a real 3.5″ floppy disk, using my PC – Unfortunately the utility does not allow the use of USB drives, so a real drive is required.

Inserting the disk in the Spectrum and selecting the “Loader” option, caused disk activity on both drives, but eventually the 3.5″ drive started to seek and fairly quickly loaded the game in question. Success!

At the moment the drive is a little messy. I probably really ought to tidy it all up, possibly replacing the jumpers with toggle switches. It works reasonably well, although it requires a PC with a internal drive to write the disks and is limited in the games it can play by what was published on floppy disk.It has, however, been constructed from spares and cost me nothing to make.

If anyone does read this a replicate the process, I wish you luck, but you do it at your own risk. I will not be held responsible for any damage to yourself or anything else.